CPP GLOBAL (ASIA) Ltd. is a branch of Westfall Technik Inc. in China. Westfall Technik Inc. is a global holding company that creates high-end manufacturing solutions for plastic parts production in healthcare, consumer packaging, and light industry markets by selectively integrating specific core competencies.

CPP GLOBAL (ASIA) Ltd. is established in 1988 and belongs to CPP Global Group of USA. It is located at Kaiping City, Guangdong, China. The overall floor space is approximately 30,000 meters. The production workshop is about 15,000 square meters. Dormitory is 3000 square meters.

In order to improve our marketing competitiveness in China and even around the world, our company has a development and design, production, and efficient management team to provide customers with a complete set of services, including development, design, engineering, injection molding, blow molding, high-speed assembly, spray, metalizing, and other decorative processing technologies. We do our provide customers with solutions and meet their various personalized needs.

We are professional at product design and development for cosmetic packaging. In addition, We have more than 20 years cooperation with Estee lauder, L'Oreal, Bobbi Brown, Clinique, Avon, Origins. M.A.C. which are famous companies in all over the world in term of product design and development. At the meanwhile, we have a good cooperation with Sisley and Lancome of overseas and also keep doing business with Mao Ge Ping, Carslan, Perfect, Jala, Colorkey which are well known in China for several years.

The company's operation system is perfect, and the organizational structure is clear and complete, so we're able to offer a complete set of packaging materials

services for customers from product design, mold design, mold manufacturing, injection molding production, surface processing to finished product assembly. The company

not only meets customer's personalized needs, but also have different advantages. For example, short cycle, low cost, and high quality. Currently we have 44 sets Injection machines, which are brand Toshiba, Nippon Steel, Nippon Fine, Liansu, Haitian, from 50T to 650T. They're including two - color injection molding machine and blow molding machine with Five axis servo manipulator that can be Automatic pickup for running production. The automatic conveyor belt carries the product to the independent clean operation room for full inspection and packaging in order to ensure short production cycle and stable product quality. Daily production of compact component can reach 1 million pcs, and caps can reach 2 million pcs. The injection molding machine has large mold space, complete screw types, and we have a high-level injection molding technical team as well. We have achieved remarkable results in terms of the transparent thick wall rubber parts that it can reach 25mm transparent wall thickness.

Mold Design and Mold Manufacturing Center,our stock toolings are over 1000 sets.We have 3 sets of CNC, as well as a number of lathe, milling, planing, grinding, EDM equipment.Using high precision mold measuring 3D measuring center to ensure the dimensional accuracy of mold machining.We have ability to handling product design as well as mold design and manufacture. We can offer a full set service for you which including molding injection, silk screening, painting, VM, assembly, etc. Furthermore, we have a professional surface decoration design team to explore new techniques for customers.

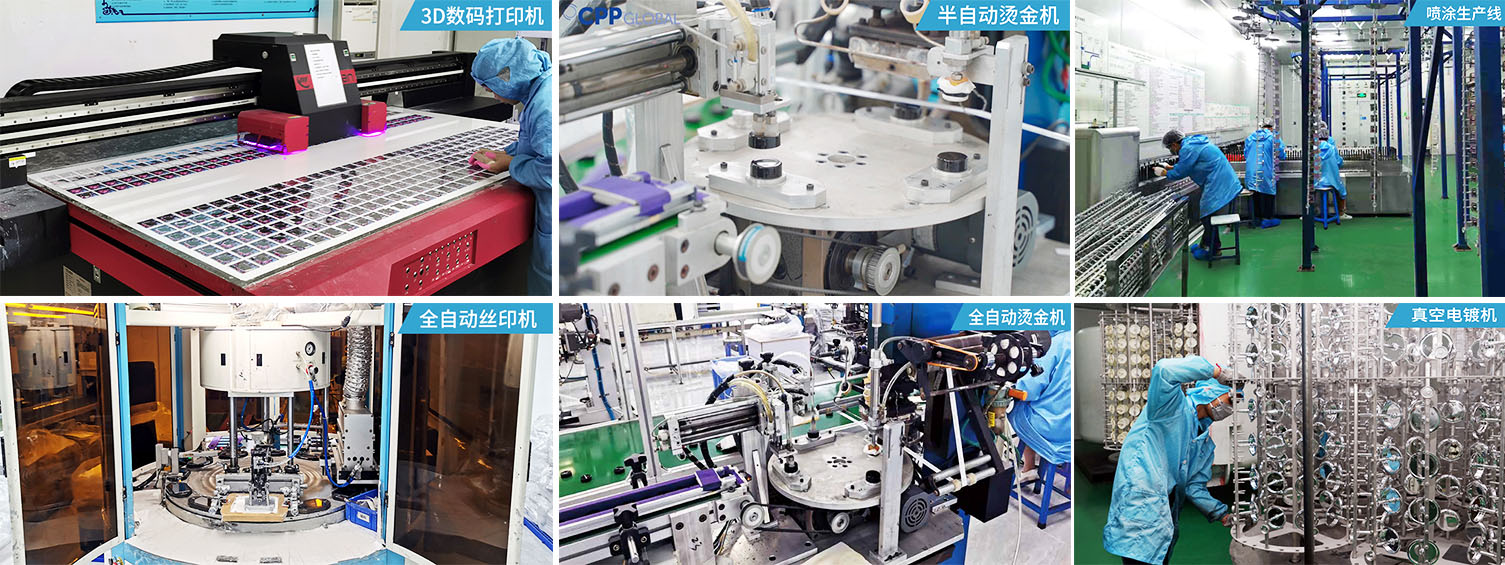

Processing workshop has a number of advanced processing equipments, such as automatic screen printing machine, hot stamping machine, automatic hot stamping machine, 3D printing, self-de-veloped automatic ultrasonic machine, automatic injection machine, four spraying lines, vacuum electroplating machine, which can realize printing, bronzing, 3D printing, radium carving, thermal transferprinting, spraying, vacuum electroplating, colorful plating and other processes on the surface of packaging materials. Capacity can match injection workshop capacity.The daily output of silk printing is about 300,000, bronzing is about 110,000, 3D printing is about 3,300, spraying is about 200,000, electroplating cartridge is about 70,000, cover is about 150,000.

The assembly workshop has 15 flexible assembly lines, 6 automatic assembly lines for compacts and 6 automatic assembly liners for caps, which can achieve an average daily assembly capacity of 500,000 compacts and 300,000 caps. Meanwhile, we have a strong automation equipment design and production team, so we can according to customer's orders at the beginning of the project synchro-nous development for automatic assembly, to reduce costs, benefit customers.

The company passed the certification of 1SO 9001:2008 SGS in 2012, and it has been upgraded to the 2015 version currently.

Quality Assurance:

CPP ASIA pursues high quality components and assembly solutions perseverely by understanding customer's demands. Leveraging its proprietary injection molding equipment, precision molds and plastic processing expertise to serve the global consumers, packaging and medical markets.

CPP ASIA is committed to delivering value to our customers and exceeding industry and customer expectations by investing in our staffs, technology, equipment and processes.CPP ASIA Strives to achieve High quality production and improve customer satisfaction by using QbPD, QbPVal, QbPC and QbPVer. Reduce process variability and eliminate product defects by using QbCI.

CPP ASIA relies on an effective quality management system (IQMS) and associated process controls to meet all applicable regulatory requirements, and uses a risk-based approach to provide our customers with reliable products in terms of safety, effectiveness and reliability.